In today's technology-driven world, LCD (Liquid Crystal Display) technology stands as a cornerstone in the display industry, powering everything from simple digital watches to sophisticated high-resolution screens in smartphones, televisions, and digital signage. With the rising demand for tailor-made solutions in various applications, understanding the intricacies of custom LCD display costs becomes essential for businesses and consumers alike. This article delves deep into the factors that influence the pricing of custom LCD displays, shedding light on the manufacturing process, customization options, and other critical aspects.

Understanding LCD Technology and Customization

Before we explore the costs, it's crucial to have a fundamental understanding of LCD technology and what customization entails. LCDs operate by blocking or allowing light to pass through liquid crystals, which are manipulated by electric currents. The customization of LCD displays can range from simple alterations like size and shape to complex modifications involving resolution, contrast ratios, interfaces, and backlighting technologies.

Key Factors Influencing Custom LCD Display Costs

1. Design Complexity

The complexity of the design is a primary factor that affects cost. Custom specifications such as unique shapes, sizes, or the integration of touch screen capabilities can significantly increase the research and development (R&D) expenses involved in creating a prototype.

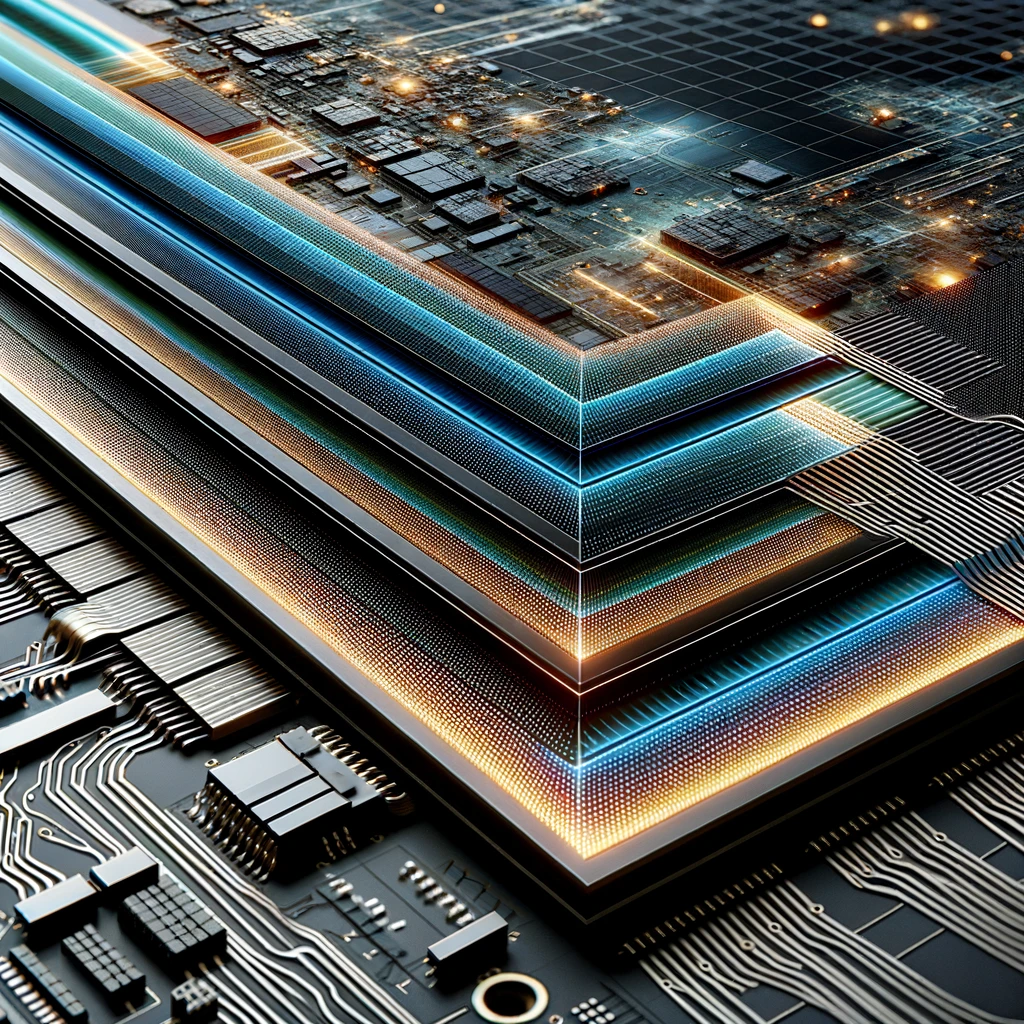

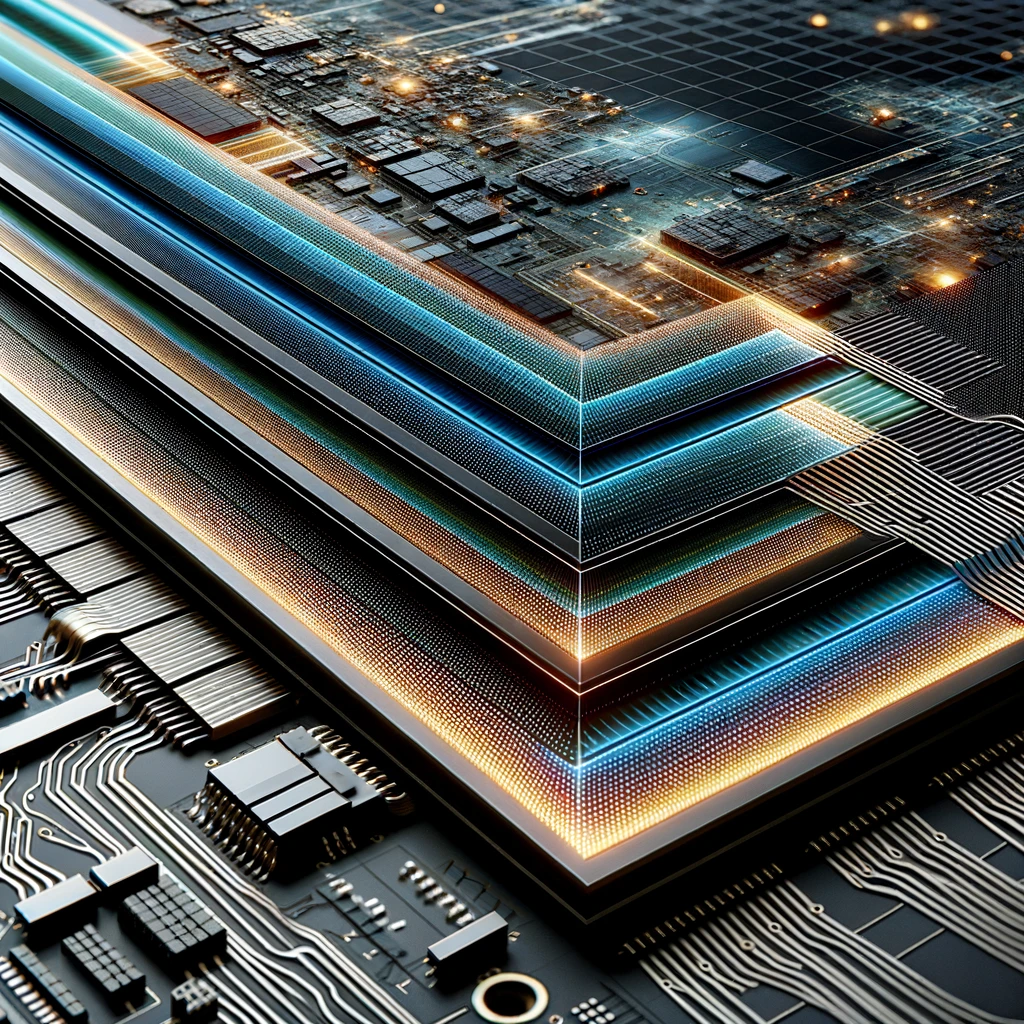

2. Materials and Components

The choice of materials and components plays a crucial role in determining the overall cost. High-quality materials like advanced liquid crystal compounds, durable substrates, and efficient backlighting elements can drive up prices but are essential for superior performance and longevity.

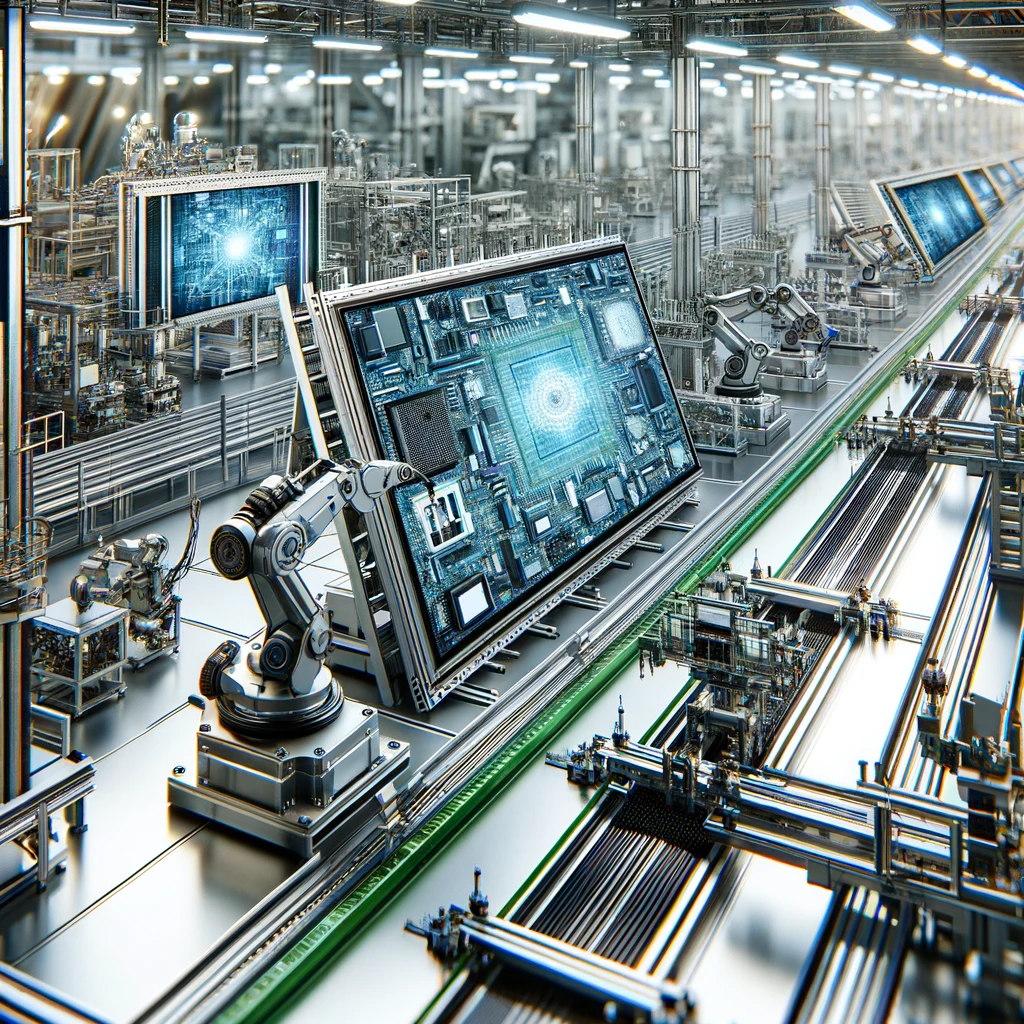

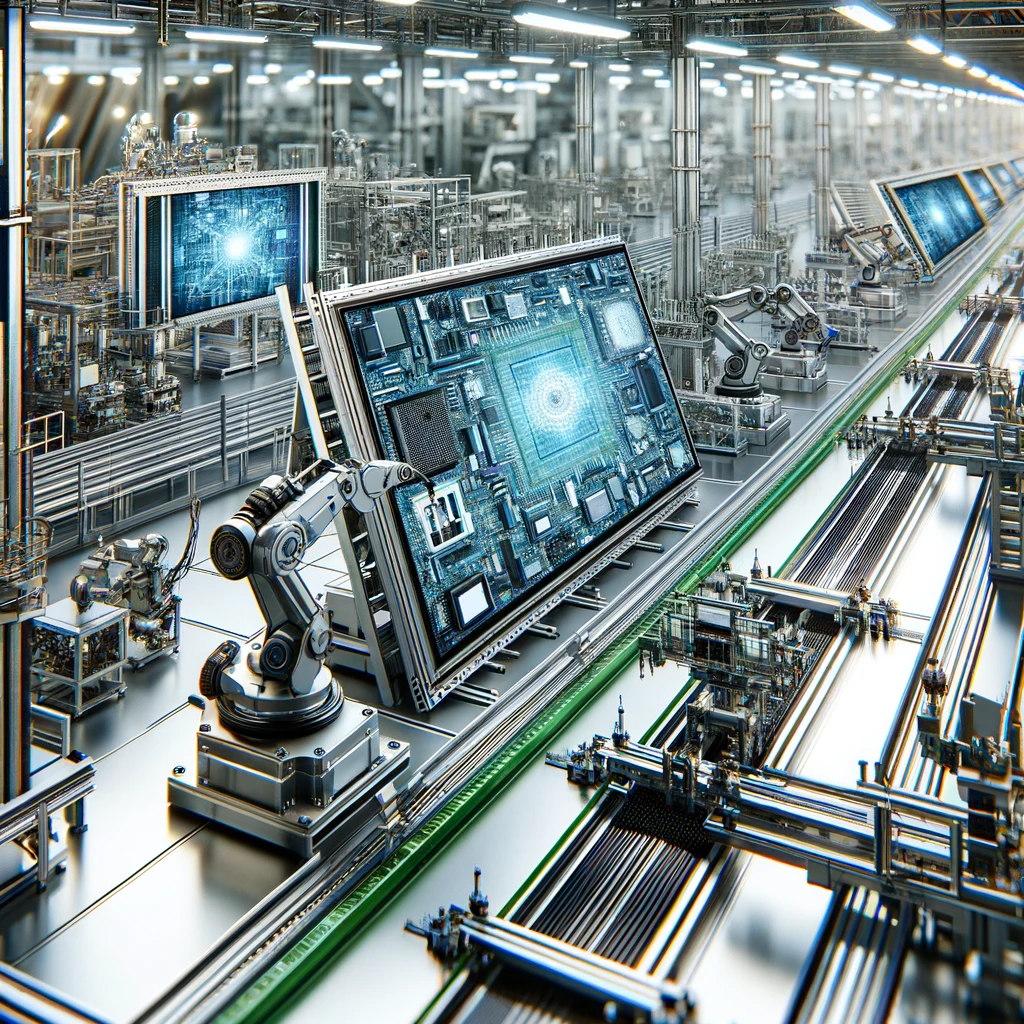

3. Manufacturing Process

The manufacturing process for custom LCD displays involves several stages, including design, prototyping, testing, and mass production. Each phase incurs costs related to labor, machinery, quality control, and adjustments to meet specific requirements. The more customized the order, the higher the manufacturing costs due to the need for specialized equipment and skilled labor.

4. Volume

The order volume significantly impacts the cost per unit. Producing custom LCD displays in bulk typically results in lower costs per unit due to economies of scale. However, small-scale orders of highly customized displays can be considerably more expensive.

5. Technological Advancements

Incorporating the latest technological advancements such as higher resolutions, better contrast ratios, and energy-saving features into custom displays can also affect the cost. While these innovations enhance the user experience, they require additional R&D and more sophisticated manufacturing processes.

Custom LCD Solutions: A Case Study

To illustrate the cost breakdown, consider a hypothetical case study of a company seeking a custom LCD display for an industrial application. The company requires a display with specific dimensions, rugged design for outdoor use, high brightness for readability in direct sunlight, and touch functionality for user interaction. The development process would include:

Initial Consultation and Design: Engineers and designers work with the client to finalize the specifications and create a detailed design.

Prototype Development: A prototype is developed to test the design's feasibility, which involves material procurement, assembly, and rigorous testing.

Mass Production: Once the prototype is approved, the display goes into mass production, where economies of scale can reduce the overall cost per unit.

Conclusion

Custom LCD displays offer unparalleled benefits in terms of performance, aesthetics, and functionality tailored to specific needs. However, the cost of customizing an LCD display is influenced by several factors, including design complexity, materials and components, manufacturing processes, order volume, and technological advancements. By understanding these factors, businesses and consumers can make informed decisions when investing in custom LCD solutions.

In an era where display technology is constantly evolving, staying informed about the factors that contribute to the cost of custom LCD displays is crucial. Whether for industrial, commercial, or personal use, the investment in custom LCD technology can lead to innovative applications that enhance user experiences and meet precise requirements.